The Netflix documentary charts the economic and social issues that converge when the Chinese company Fuyao moves into a former General Motors plant in Ohio.

“America is a place to let your personality run free.” So goes a cultural briefing for incoming Chinese workers at an auto-glass factory in Dayton, Ohio, the subject of Steven Bognar and Julia Reichert’s new Netflix documentary, American Factory. “As long as you’re not doing anything illegal, you’re free to follow your heart. You can even joke about the president. Nobody will do anything to you,” a representative of the Chinese manufacturer Fuyao tells his somewhat disbelieving employees.

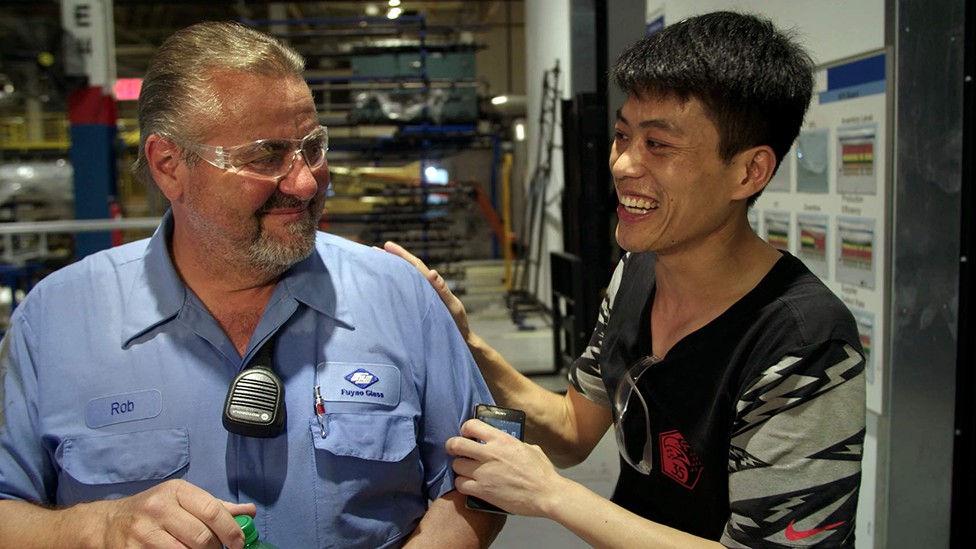

In 2014, Fuyao bought part of a closed General Motors assembly plant in Ohio and created thousands of jobs, revitalizing a local industrial sector that had fallen on desperately hard times when GM left town during the 2008 recession. American Factory charts the wave of exultation that greeted the arrival of Fuyao, followed by culture clashes, growing pains, and eventually forms of internal and external pushback that had been largely unknown to the company. The film is a captivating examination of the notion of “freedom” promised in that opening presentation: how limited and illusory it can be, and how widely the concept’s meaning can vary around the world.

Fuayo

Fuyao Glass Industry Group Co., Ltd. (Chinese: 福耀玻璃工业集团股份有限公司) is a manufacturing company in the People’s Republic of China, engaged in the production of float glass, automobile glass and construction glass. It is one of the largest auto glass producers in the world,[1] with customers including large international automobile manufacturers such as Ford, General Motors, Subaru, and Volkswagen Group. It was established in 1987 as a joint venture company and is headquartered in Fuqing, Fujian. It was listed on the Shanghai Stock Exchange in 1993 and on the Hong Kong Stock Exchange in 2015.

Cao Dewang founded Fuyao in Fuqing, Fujian Province 1987 with several business partners.[4] He had previous experience having taken over management of a glass factory owned by a local government. While there were few major buyers of automobiles at first, his company targeted the market of replacement glass for large numbers of imported vehicles into China.[5] The name derives from the first character in the name of the city of Fuqing (福 fú) and the Chinese word meaning “shine” (耀 yào).

The company formed a joint venture with Saint-Gobain in 1996 with the French firm’s 51 percent stake valued at $15.3 million. Three years later, Cao bought the stake back for $30 million.[6]

Fuyao became an original equipment manufacturer to General Motors in June 2006. Later that year, it signed an agreement with Goldman Sachs to sell 111 million new shares, to raise about ¥890 million ($137 million). In March 2007, Fuyao landed a contract supplying Bentley. That year, foreign sales contributed ¥5.17 billion, or almost $795 million, almost 28 percent of its sales that year. By that time, it was the fifth-largest maker of automotive glass in the world, with an estimated three percent market share, and held 60 percent market share of the automotive glass market in China.[

Fuyao Glass America Inc.[edit]

In 2014, Fuyao began looking at establishing a factory presence in the United States, considering several sites in Ohio and Michigan before deciding on the former General Motors Moraine Assembly plant in Moraine, Ohio.[7] Its initial commitment to the factory, which was made public in January 2014, was to buy 1.4 million square feet of the plant from Industrial Realty Group and invest $240 million into an auto glass production facility, which would create 800 jobs.[7] In 2014, the company bought a float glass plant in Mount Zion, Illinois. In 2016, it announced an additional $131 million investment to add additional after-market glass lines at the plant, bringing it to 24 production lines. In exchange it received $6.6 million in incentives from JobsOhio. By then, the company planned to produce enough auto glass for 4 million to 5 million automobiles a year,[8] taking advantage of the recent contraction in the U.S. auto market during the Great Recession.[9] By the time the plant entered full-scale production in October 2016, it had invested $1 billion in the U.S. subsidiary. It has long-term plans to grow to 5,000 employees in the United States.[10] As of early 2020, Fuyao had opened additional operating facilities in Greenville, South Carolina and Detroit, Michigan.[11] By 2018, after losing tens of millions of dollars per year, the plant turned its first annual profit.